Support

Support

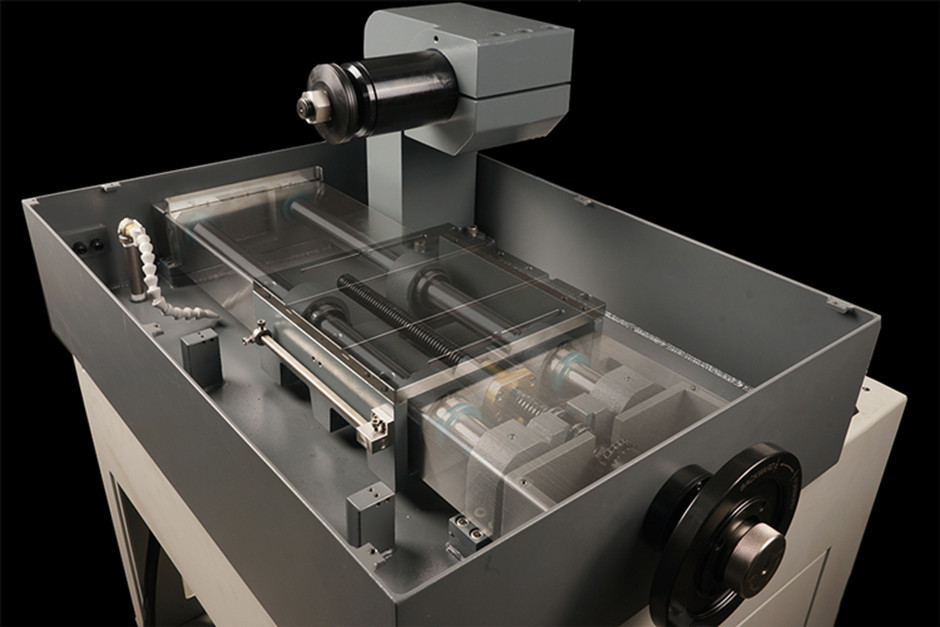

Large Automatic Metallographic Cutting Machine Product Serial:TNC-255ASL/TNC-305ASL/TNC-355ASL-FA Br

Product Description

- MIT Taiwanese system

100% of the Taiwanese design team brings the top suppliers from various industries, and connects with experts in the field of professional metal manufacturing and the academic field of fashion to create a fashion cutting machine suitable for the use of the metal industry and the technology industry. It is widely used in scientific research institutions, Automobile industry, aerospace, metal manufacturing, heat treatment, etc.

For related fields: qualitative hardness, heat treatment technology research and judgment, carburizing and hardening layer thickness, induction hardening, welding area hardness, hard bonding, electrical parts observation related technology development and quality management and other pre-processing processes.

- Bright and user-friendly operating space

The cutting room is the main area for the daily work of the operator. The new TNC re-plans the space size and lighting source according to the user's height and operating habits. The bright working environment can improve the efficiency and comfort of the user, so that cutting is no longer one. A boring and messy job.

- Large fast and stepless slide fixture (TNC-355ASL)

The new fast positioning fixture combines high flexibility and high clamping force, which improves the safety performance for the clamping of complex products. The stepless slide rail design meets the requirements of different size products without repeated disassembly and installation of different fixtures. Maximum opening size: 210mm

- Intelligent feed function (optional)

According to the cutting characteristics of different materials, the corresponding relationship between the current value and the cutting load is used to carry out anthropomorphic reciprocating cutting. This function can cut stronger and harder materials, and increase the life of the cutting blade, thereby reducing costs.

- Small high-strength screw afterburner clamp (TNC200/230/255)

It is a special screw afterburner fixture suitable for small products. It is cut and processed from a single piece of steel. It is strong and durable. After heat treatment, it is the best choice in terms of mechanical properties and corrosion resistance.

- Magnetic filter device (optional)

It can reduce the number of manual cleaning of the circulating water tank. And reduce the deterioration of cutting fluid caused by residues, prolong

Service life, easy to collect residue, reduce cost, and reduce the blockage probability of cooling system.

- Laser Tool Setting System (Optional)

Laser tool setting system simplifies the complexity of tool setting during cutting.

- Maintenance convenience

For the TNC series cutting machine, the feed system is packaged in the stainless steel protection mechanism, which greatly reduces the maintenance rate. You only need to add lubricant ester to the feed screw regularly. You can also call the TN service phone to purchase regular maintenance services. System maintenance work.

- The whole machine has passed CE certification

Automation function

- All series use reinforced safety glass

- Consumables compatibility