News

News

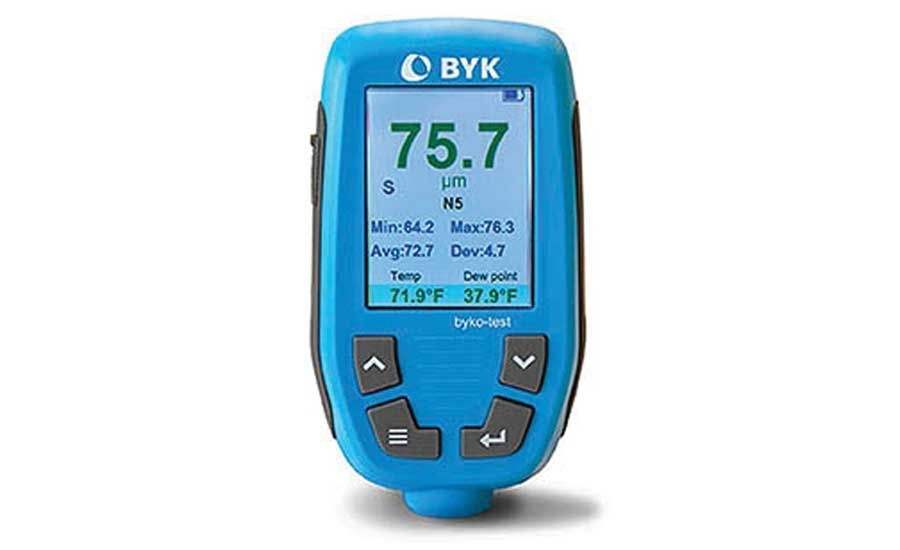

Byko-Test Film Thickness Measurement Gage 3790 / 3791 (Lite)

Product description:

Compared with 3791 (Lite), the 3790 non-destructive electronic film thickness gauge has an additional dew point function.

Coating thickness is an important parameter that should be measured regularly. Appropriate film thickness will affect the coverage, appearance and protective performance of the coating. If the coating is too thick, it may cause excessive drying time, causing cracking and peeling of the coating. Coating thickness measurement can monitor the coating process and maintain appropriate coating properties. The film thickness gauge may apply either a nondestructive test or a destructive test.

Non-destructive film thickness gauge uses the principle of induction of magnetism for iron substrates and the principle of eddy current for non-ferrous surfaces.

Features :

* Automatic substrate recognition

* Zero point calibration

* Hi/Low tolerance settings for pass/fail warning

* Continous measurement mode

* Stability mode warns user when instrument is tilted preventing wrong readings

.jpg)

Standards:

Technical Attributes:

|

Substrate |

Steel or Iron, Non-magnetic metals: aluminum, copper, brass, zinc, stainless steel |

|

Measuring Range |

0 - 2000 µm;0 - 79 mil |

|

Accuracy |

±2 µm + 3% des Messwertes ±0.08 mil + 3% des Messwertes |

|

Temperature measurement range (model 3790) |

0 - 50 °C |

|

Temperature accuracy (model 3790) |

±1.5 °C |

|

Humidity measuring range (model 3790) |

0 - 100 % RH |

|

Humidity accuracy (model 3790) |

20 - 70 %RH:±4% 0-19 & 71-100 %RH:±6% |

|

Minimum substrate thickness |

Fe:0.2 mm; NFe:0.05 mm |

|

Minimum bending ratio |

Convex surface: 5 mm; concave surface: 30 mm |

|

Memory |

1,000 |

|

Weight |

0.16 kg |

|

Dimensions: L x W x H |

11.5 x 6.7 x 4.4 cm |