News

News

Infrared Pyrometer, Sulfur Processing Service

Model: HIR

Brand: Delta Controls

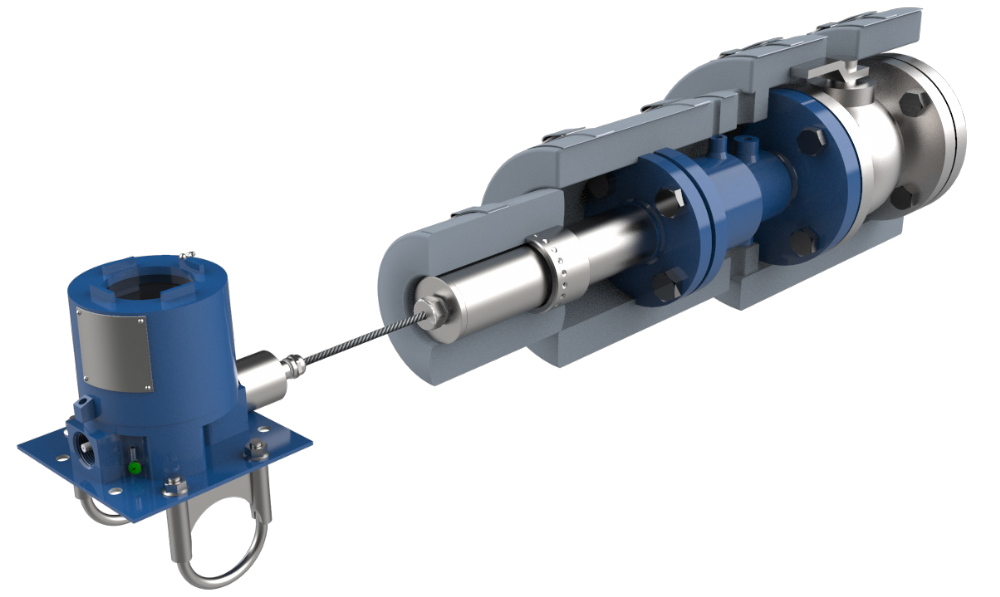

The Delta Controls Model HIR Pyrometer detects the intensity of infrared energy radiated by the refractory hot face in a Claus thermal reactor. This sensed energy is converted into an electrical signal, which accurately displays the temperature. This is accomplished using narrow-bandpass optical filters and special sensors. The selected sensing spectrums avoid significant errors due to luminosity and absorption.

The HIR is designed to be maintenance free. The lens, sighting window, and nozzle are kept at a high temperature to avoid sulfur accumulation and the need to perform frequent periodic maintenance. This is accomplished by the steam jacketed lens assembly design that prevents sulfur from condensing onto the lens window or accumulating in the nozzle. In addition, the loop-powered, drift-free HIR electronics do not require frequent calibration service. Due to the high temperatures at the lens window, the electronics are mounted away from the reactor and connected to the lens assembly by a 10 feet (3 meters) armored fiber optic cable, eliminating the need to provide cooling to the electronics housing. If it is impractical to mount the electronics within 10 feet of the reactor mounting nozzle, the fiber optic adapter wires can be extended up to an additional 25 feet (8 meter) using the remote sensor option.

The electronics employ a dual-wavelength ratiometric measurement that is unaffected by flames, partial nozzle obstructions, or occluded (coated) lens windows. In essence, the measurement is based on the wavelength of the light instead of the intensity, as is usually done with a single wavelength measurement. In addition to the temperature, the amount of blockage can also be measured and used to generate an alarm.

The HIR ideally operates in conjunction with, or independently of, Delta Controls Thermocouples to achieve turnaround-to-turnaround reliability with minimum maintenance. This is particularly advantageous when supplemental oxygen is employed or during upset conditions. The use of both technologies eliminates commonly caused errors and vastly improves overall system reliability.

A three section insulation system is included with each Model HIR. The insulation system is specifically engineered so the Model HIR maintains proper temperature along the isolation valve, steam jacketed assembly, and lens assembly. The insulation system retains the heat produced by the steam jacket assembly. This system maintains the temperature above the sulfur freezing point and ensures sulfur cannot accumulate on the lens and reduce the amount of infrared energy received.

Application Overview:

Model HIR uses infrared pyrometry to measure temperature in Claus sulphur recovery units, partial oxidation reactors, coal gassifiers, and chemical incinerators.

The HIR unit is well suited to applications where the sensor must “look through” flames, incandescent gases, and how gases to measure the temperature of an object or a refractory hot face.