Support

Support

.png)

Coating Thickness Handheld Gauges

ADVANCED METALLIC COATING MEASUREMENT

The CMI243® is an essential tool for any metal finisher. It has a flexible and easy-to-use design with the ECP-m probe which uses phase-sensitive eddy current technology.

With the CMI243® using the ECP-m probe it is possible to accurately measure metallic coatings over ferrous substrates - even on small, odd-shaped or rough surfaces.

This gauge is ideal for use on fasteners and transportation components, featuring user-friendly controls and performance that is comparable to X-ray fluorescence (XRF) instruments.

For added value, the CMI243® can be expanded with a magnetic induction probe for measuring paint and other coatings on magnetic substrates.

Common measurement applications for these gauges include:

Components for automotive/aerospace

Appliances

General industrial parts

Architectural pieces

KEY FEATURES:

Battery operated.

Eddy current technology.

I Reliable and accurate.

PHASE-SENSITIVE EDDY CURRENT TECHNOLOGY

More reliable than conventional eddy current and magnetic induction gauges, especially for small parts or parts with complex geometry.

Accuracy within ‡1% (with reference to standards) and precision within 0.3%.

ADVANCED ECP-m PROBE

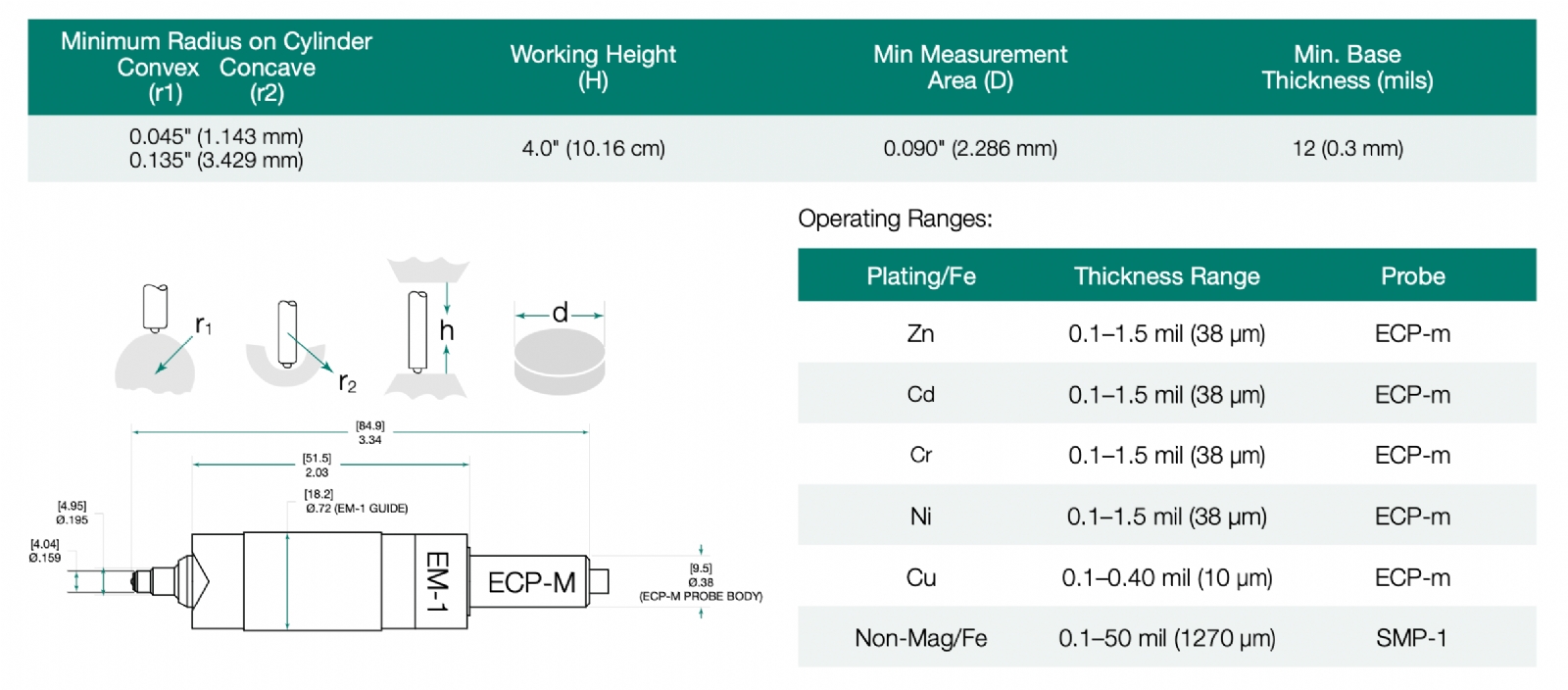

Our ECP-m probe was designed specifically for difficult metallic coating applications. This probe can measure metallic coatings, such as zing, nickel, copper, chrome or cadmium on ferrous substrates. Its tip provides easy measurement of small, odd-shaped or rough components.

.png)