最新消息  Latest News

Latest News

DIN Abrasion Tester - A Good Rubber Inspector

DIN Abrasion Tester – A Good Rubber Inspector

Critical to the quality assurance of rubber materials is their abrasion resistance. Abrasion is a major problem with rubber products because it determines the durability and strength of the material. It is the undesirable effect of exposure of a material or product to regular use.

The abrasion resistance of rubber materials like tires, foot wears, etc. is readily known by a method known as Din abrasion testing.

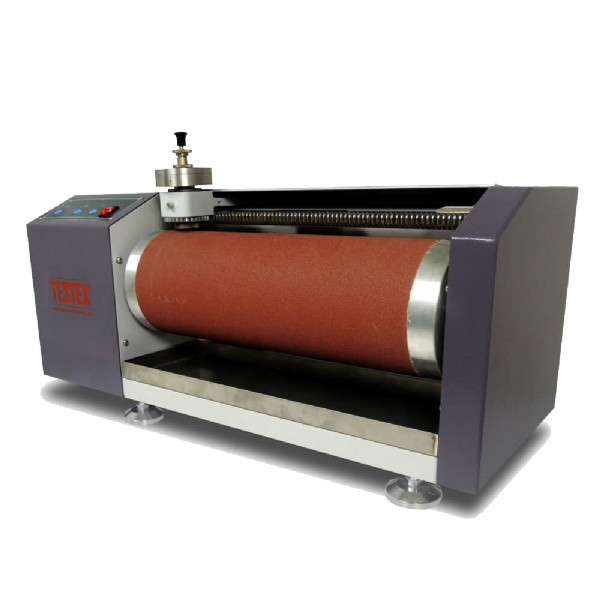

The machine used in testing the abrasion of rubber products is called a DIN abrasion tester.

The DIN abrasion tester is very active in testing the abrasion resistance of any rubber material as the rubber material is subjected to a highly abrasive environment of the testing machine.

BENEFITS OF PERFORMING THE ABRASION TEST

Abrasion plays a critical role in many rubber applications. It explains the durability or lifespan of the rubber material. There are several means of performing the abrasion test on rubber but the best form of the test is the DIN abrasion test done with the DIN abrasion tester.

The DIN abrasion tester measures the resistance of vulcanized rubber samples and also tests the final product.

Also known as Rotary Drum Abrasion tester, the DIN abrasion tester has an abraded surface where the specimen rubber is subjected to continuous contact with this surface that is often adjusted to a particular grade of abrasion.

The volume of loss recorded on the specimen rubber due to the abrasion is calculated to give the resistance index.

APPLICATIONS OF THE DIN ABRASION TESTER

The DIN abrasion tester can be used to measure or test the abrasion on many products that are made of rubber such as conveyor belts, tire, shoe soles, power transmission cables, hoses, rubber floor coverings, etc.

The method of abrasion testing is useful in measuring the resistance of rubber in environments with high abrasion and also to ascertain the regularity of wear behavior.

The DIN abrasion tester gives you the best results for comparative testing, quality analysis, and research and development work.

HOW THE DIN ABRASION TESTER WORKS

The DIN abrasion tester is a tool that is reliable in measuring the abrasion of rubber and elastomers.

Before telling how it works, let us have a quick glance at the machine’s features.

Features

• Adjustable limit switches

• Rotating sample holder

• Sample cutting die for precise sample cutting

• Steel rotating drum

• Strong base plate

• Interchangeable weights of 5N and 10N as contact force

• Material body made of steel

The DIN abrasion tester is built in a solid and sturdy metal base plate and made with a bright zinc or chrome plating to make it corrosion free.

The machine has a highly abrasive material that is held in place by a holder. This holder moves over the test specimen at a constant speed. The test specimen is usually put on a circular drum that is just underneath the holder. Before the specimen is made to undergo abrasion, the original size is recorded.

The abrasive holder is made to move over the rubber specimen at a constant speed and this movement causes some abrasion of the specimen.

After the testing procedure, the size of the specimen is recorded and the volume of its size reduction is used to analyze the abrasion resistance of the sample.

CONCLUSION

If you are a manufacturer of any rubber products, the DIN abrasion tester is an essential machine in that category. It is highly important as a manufacturer that you know the quality and durability of goods that you inject into the market if you wish to maintain your integrity in your chosen field.

The best way of finding out the abrasive resistance of rubber materials is via the DIN abrasive tester.