News

News

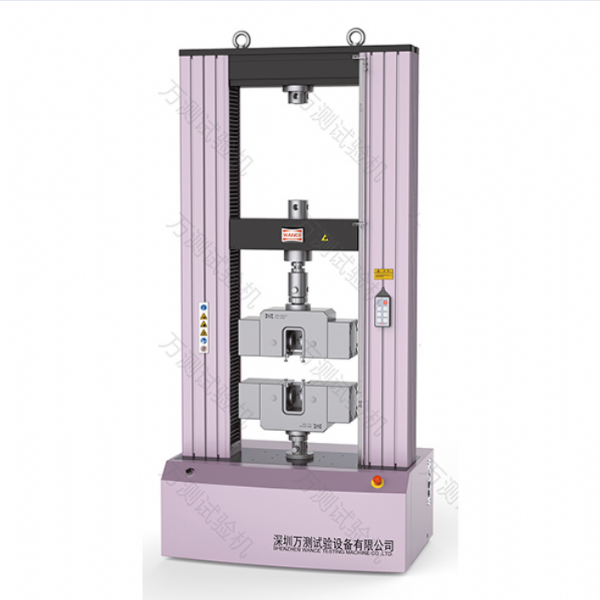

Microcomputer controlled electronic universal testing machine

Equipment overview

The ETM series D-type door-type microcomputer-controlled electronic universal testing machine can be used for force measurement tests such as tension, compression, bending, and shearing with a maximum load of 300 kN. The main machine has a floor-to-ceiling door structure, and the middle beam is guided by a high-precision guide rod, which has high rigidity and good linear motion characteristics. In addition, a wide range of fixtures, deformation measurement and other accessories can meet almost all customer needs. The supporting flexible and easy-to-use TestPilot software makes the user testing process easier. Testing solutions cover plastics, metals, automotive industry, building materials, textiles, paper & board, food & packaging, composites and more.

Features

Rack features

Imported AC servo motor drive, high precision and fast response;

Sensors imported from the United States have high precision and good stability;

The middle beam is guided by a high-precision guide rod, making the whole machine highly rigid and running smoothly;

Different test spaces are available to choose from to facilitate customer operation.

Extra large test width to meet customer needs to the greatest extent;

Controller features

The measurement resolution of force and deformation reaches 1/350000 of the full scale;

The sampling frequency can be as high as 120Hz;

Based on the DSP system platform in the high-end industrial control field, it integrates measurement and control, with more powerful functions and more stable performance;

It adopts three closed-loop full digital control of force, deformation and displacement, and automatically switches between control loops with smooth transition. The control algorithm adopts advanced neuron adaptive PID control algorithm, which does not require cumbersome PID parameter settings, and beginners can easily complete professional test tasks;

8 channels of 24bit A/D high-precision data acquisition channels combined with advanced digital filtering technology make the data collected more accurate, stable and reliable;

3 channels of high-speed photoelectric encoder (5MHz) signal acquisition channels, optional more measurement accessories that output optical code signals;

Plug and play interface makes it easy to expand various measurement accessories;

Using ultra-large-scale programmable digital integrated circuit design, it has small size, low power consumption, less heat generation, and more stable and reliable operating characteristics.

Software features

TestPilot software provides a simple and intuitive operation interface, powerful user-programmable interaction capabilities, complete analysis and reporting functions, and a large number of built-in standard test methods for testing various materials or industries. That is, it can meet the simple, easy-to-use, and efficient requirements required for quality control, and it can also meet the personalized testing requirements required by scientific research institutes for in-depth study of material properties.

.png)